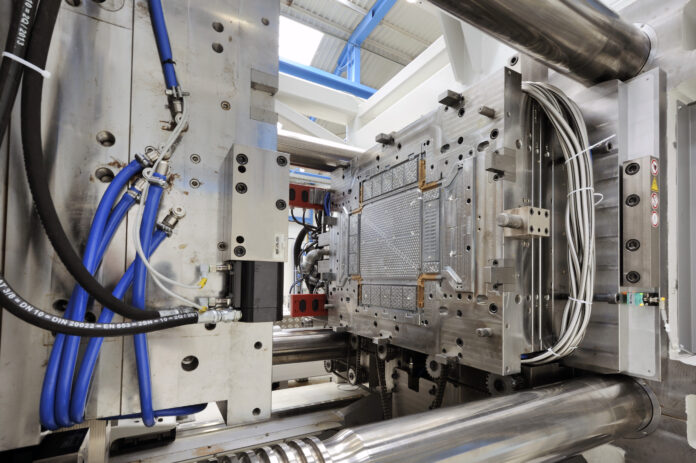

Plastic molding is the best choice for manufacturing of plastic components. The process has many advantages like durability and enhanced efficiency. What do you consider when choosing any plastic injection molding service?

Plastic component manufacturing can be a complicated process. You need to check some critical factors when choosing the company to use. The ideal company should fit your products, product needs, and industry. Use the following seven factors to aid you in the selection journey.

1. Excellent design team

Among the vital aspects of plastic molded parts is design. You need to select a company with an excellent design team. The team should work to ensure that you get the final results that you desire. It’s essential to start with clear concepts for your design.

Your design process stage is critical in a project. It turns projects efficiency based on time and cost. A company with a great team will help you achieve your objectives.

2. Production capacity and volume

Narrow down the selection based on the size and volume of the production. Different molders major in various capacities. Low and moderate production volumes are ideal if you need testing prototypes. Some diverse applications aren’t required in high volumes. They include:

Agriculture components

Medical gadgets

Aero engineering components

Such orders are suitable for moderate-ranging injection companies.

For many productions, consider companies specializing in manufacturing more units in millions. They are ideal for small size molds.

3. A complete service ranges

Go for one-stop production solutions despite the volume and type of plastic components you want to produce. Companies that offer consultation direct from the concept stage and design are good. They can aid in creating optimal designs meeting your budget needs.

You need to think of expanded services and the technical needs during the production process. Choose an offer with a complete service range: prototyping, analysis for mold flow, and part design. Any one-stop company will aid you in creating desired products. It will consider your set budget needs and time.

4. Product application

An essential factor to check when choosing your company is product application. Your product’s intended use is vital when selecting different manufacturing stages. The stages may include design, production, and development. The ideal company should give you clear guidelines to select the plastic resins.

Different plastic parts have various properties, and these properties base on moldability, strength, durability, flexibility, and heat resistance. Plastics are in use in industries as substitutes for metals to limit weight and cost.

5. Available technology and specification requirements

Many manufacturers compromise the specification needs of a product. A trusted company should produce your parts regardless of all specifications involved. A trusted company should guide and make clear recommendations on specifications needed.

Conclusion

The factors above will help you choose a reliable plastic injection company. The company will fit your needs and product needs. Be careful in surveying and planning the project inception stages.